Shaping complex sound fields from single ultrasonic transducers

A recent article in ‘Nature’ demonstrated how acoustic holograms can be simply manufactured using commonly available 3D printers. This allows very complex sound fields to be generated from a single ultrasonic transducer. This is in contrast to the conventional approach to generating such complex sound fields which has been to use multiple transducers, each driven slightly out of phase with each other, such that their sound fields overlap to produce the desired intensity profile. Although this approach has the advantage that the shape can be adjusted electronically on the fly, it requires many parts, complex electronics and is expensive to manufacture. The holographic approach potentially allows low-cost implementations with more complex sound fields and, by using, 3D printers the necessary holographic element could be simply manufactured on a case by case basis.

This could have some very interesting applications in different areas of medicine and biotechnology. For example, it could:-

- Provide a well-defined range of amplitudes for cell growth experiments within a single micro-reactor. There is evidence that low-intensity ultrasound promotes cell growth and differentiation and researchers are experimenting to determine the optimum conditions. This would replace arrays of transducers each acting within a different micro-reactor and the associated variability in amplitude and environmental conditions.

- Provide sound fields customized for each individual patient undergoing ultrasonic therapy, informed by prior diagnostic imaging. In this way therapeutic ultrasound could be directed at the tissues and structures to be treated, maximizing the intensity at those locations and minimizing it elsewhere. Low-cost 3D printing of the diffractive acoustic element makes this a feasible proposition.

- In vitro-diagnostic-devices using functionalised particles have become an essential tool to achieve separation and high specificity. As these assays move towards low-cost and miniaturized microfluidic solutions there is a desire to manipulate and locate the functionalised particles and cells more accurately and ultrasonics is a commonly used technique. Acoustic holograms could allow the sound fields to be optimized to microfluidic geometries and be shared across many parallel analysis channels. The ability to use a single transducer could also reduce instrument cost and improve coupling reliability.

The Nature article described the manipulation of polymer beads suspended in water to place them into complex 2D geometries. The size of the hologram and transducer diameter were quite large at 40-50mm. At Sagentia we are exploring the range of geometries and applications that this can be applied to at frequencies up to 10MHz.

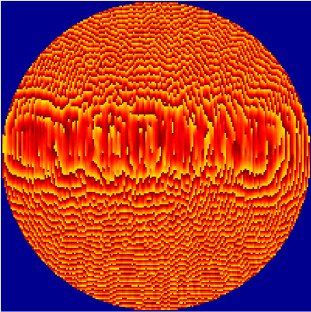

The calculated acoustic hologram produced by a single circular ultrasonic transducer and the phase plate which will produce it at 2MHz.