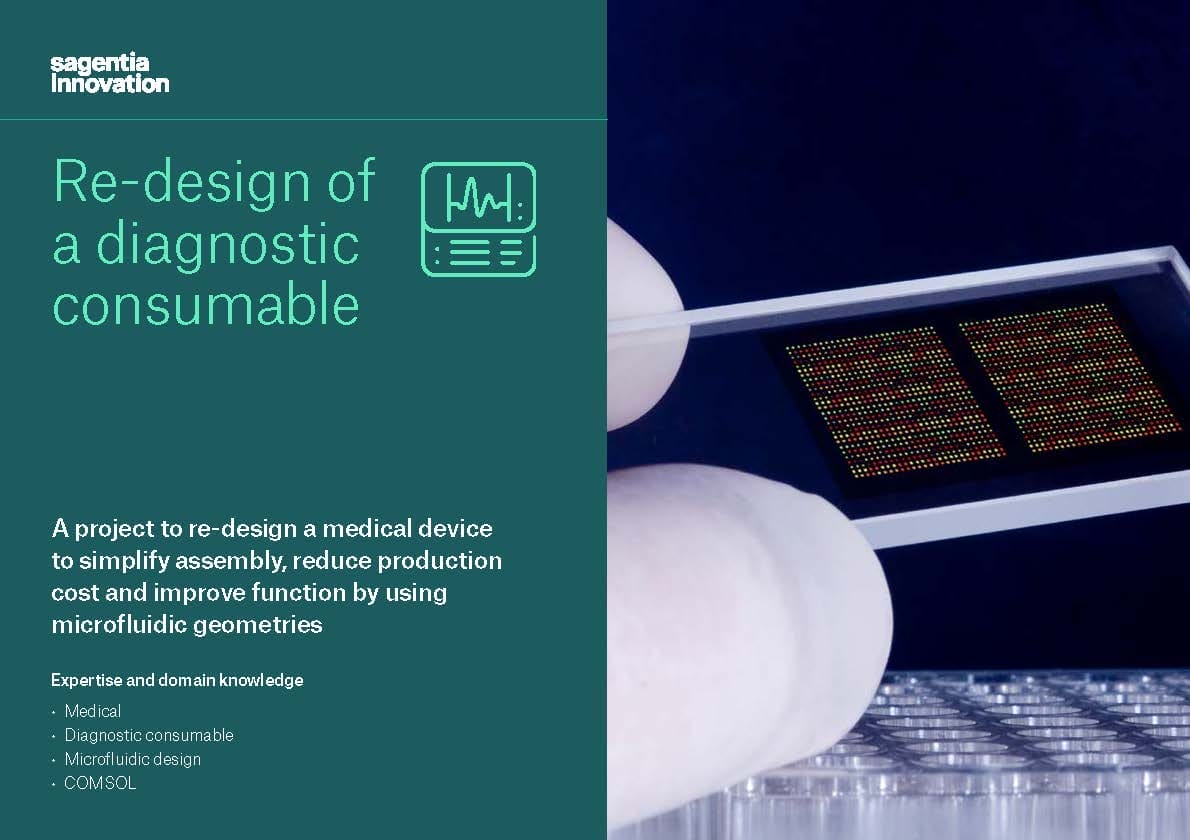

Re-design of a diagnostic consumable

A project to re-design a medical device to simplify assembly, reduce production cost and improve function by using microfluidic geometries.

Our client asked:

A market-leading medical diagnostic consumable, handling both blood and water, needed to be redesigned to increase repeatability of its fluid motions. No surface treatments could be considered on this moulded part, so microfluidic design techniques were required.

The project story:

After defining the sequence of fluid motions required within the device, we developed a COMSOL model, tested this with prototype parts and generated a design which is now in tooling. Specific functions achieved:

- Required blood sample accurately metered with tolerance of +/-1μl

- Known volume of water wicked through capillary network within a set time

- Repeatable pattern of 5μl air bubbles generated

Results: deliverables and outcomes

- Marked reduction in part count, production cost and simplified assembly

- Diagnostic precision increased through reduced variability of fluid motion

View the full case study here