MJM Holdings: Development of a novel inline coating system for extrusion systems

Our client, MJM Holdings Inc (MJM), owns global manufacturers of tubing, wire and cables that provide connectivity solutions across many markets.

MJM has developed a premium, low-friction liquid coating media to replace powder coating which offers significant advantages. However, this chemical formulation is costly, so to offer cost-effective solutions, it is necessary to precisely coat very thin (3-20um) layers. In addition, recovery and re-use of excess coating fluid in this process is a critical sustainability requirement.

MJM partnered with Sagentia Innovation to develop applicator hardware that could be retrofitted within their existing extrusion manufacturing lines.

Technical challenges

The requirement was for a coating applicator and coating system to deliver coating media precisely onto a range of cable and tubing products, which vary in diameter and other physical specifications.

It is vital that the application process consistently achieves the following parameters:

- Thin, flexible coatings which do not crack or craze when the product is bent

- The coating thickness must be consistent across the surface of the product

- Excessive application of coating media must be avoided

- Recovery and re-use of excess coating media for sustainability

- The application system needs to be adjustable so that it can successfully deliver fluids with very different chemistries, rheological properties, and those comprised of particulates

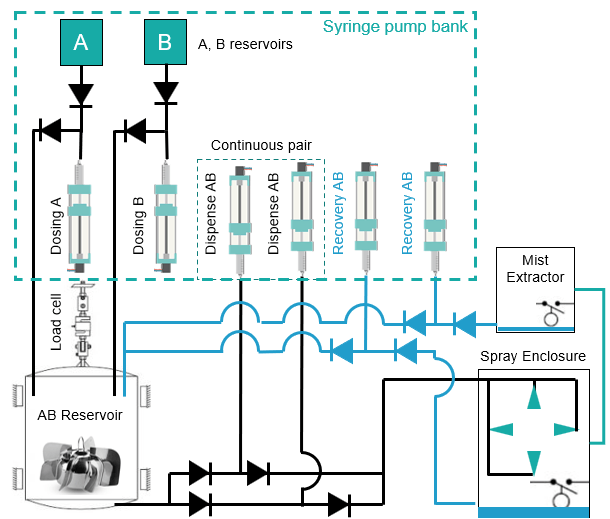

- The applicator delivers precise dosing and mixing of multi-part fluid formulations

- The formulation must be delivered at low flow rates between 0.5 and 500 ml per minute

- The system must be safe, noting that it delivers atomised or misted fluid, which must be handled and extracted appropriately in the manufacturing environment

- Optimal thermal control, as reactive fluids will auto-catalyse when mixed and heated

Our client asked

Can we develop a novel fluid application system, which integrates into an existing extrusion line, for applying thin film coatings, that improve the functionality and performance of wires, cables, and tubes?

The project story

The development was divided into phases to manage technical and commercial risks. The first phase focused on the underpinning science to determine the suitable application technology. The second phase refined the product requirements and created a system architecture to demonstrate that an engineering solution was achievable. The third phase identified the highest-risk modules and built prototypes to quantify and mitigate those risks. In the final phase, Sagentia Innovation designed, built, tested, and commissioned the complete production system.

Results: deliverables and outcomes

The coating applicator system is being used on the production line to manufacture high-performance cable and tubing products. MJM can differentiate its products by offering wire, cable, and tubing products with unique performance, such as low stiction properties that overcome issues with powder-based solutions.

Expertise and domain knowledge

- System architecture

- Fluidic control

- Thermal control

- Sustainability

- Mechanical design

- System build, integration and test

“We needed an innovative system for applying materials in a production area with limited space. Having worked with Sagentia Innovation on other projects and knowing their breadth of capabilities, made it an easy decision to partner with them. With the many challenges we all faced during COVID-19, the Sagentia Innovation team moved forward with delivering an excellent system that has met my company's needs. I credit this to their strong project management system and their excellence in developing creative solutions.”

Richard Larson, Ph.D. – Director, Research and Development