NeuraGen® 3D Production Process – Integra LifeSciences

The project story:

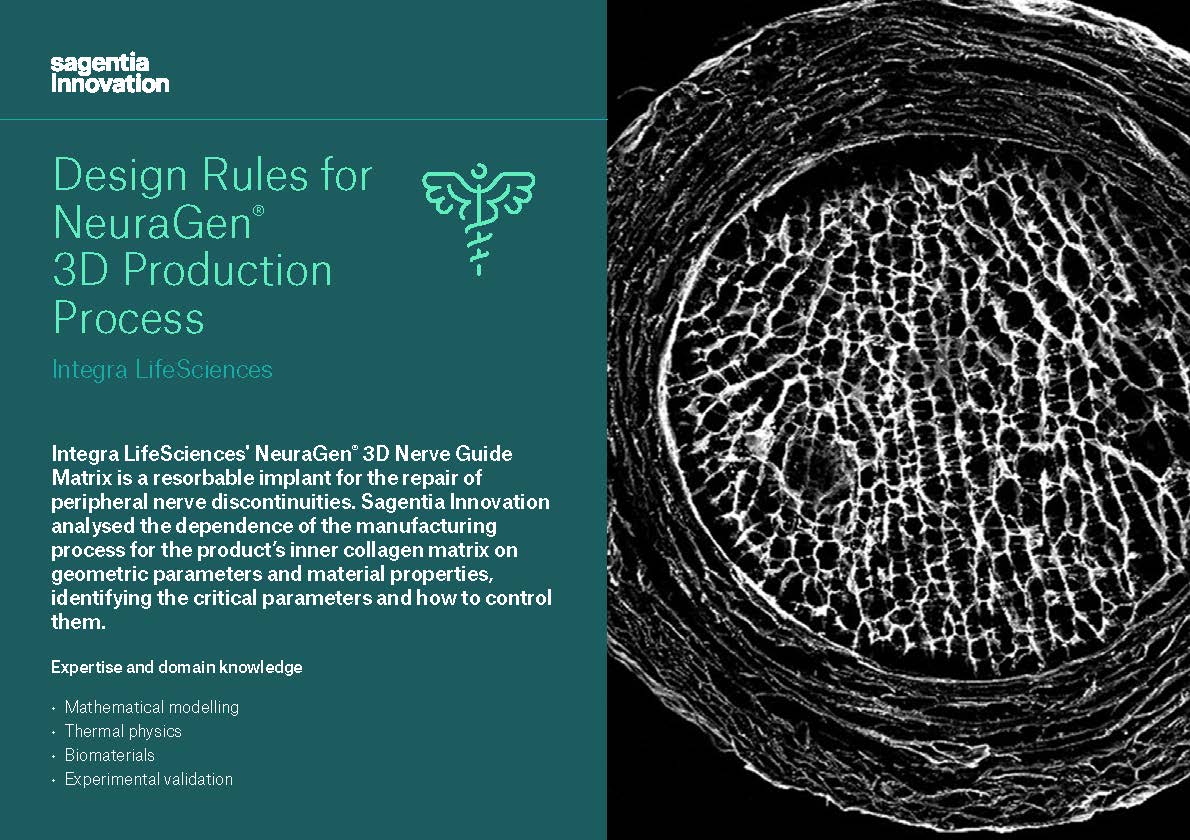

Integra LifeSciences makes the NeuraGen® 3D Nerve Guide Matrix, a resorbable implant for the repair of peripheral nerve discontinuities. It is a resorbable collagen tube filled with a longitudinally aligned porous collagen matrix, which has been demonstrated preclinically to help guide Schwann cell migration and direct axonal growth. The internal structure of the longitudinal matrix depends on a thermodynamic process that is subtly influenced by a number of geometric parameters and material properties.

Sagentia Innovation developed a mathematical model of this process that enabled the dependence on geometric parameters and materials properties to be analysed. The critical process parameters were identified, and the model was validated experimentally. We then developed a set of design rules to enable the process to be controlled at both prototype scale and production scale.

Results: deliverables and outcomes

The design rules were captured in a detailed report and transferred to Integra LifeSciences at an interactive workshop for its whole product team.

NeuraGen® 3D was launched in March 2022

“Sagentia Innovation’s work on the thermodynamics was a crucial step in translation of the product from prototype to manufacturing. I appreciated both the excellence of the work and having an external partner to educate our team on the physics.”

Simon J. Archibald, Chief Scientist, Integra LifeSciences